Input size: Up to 350mm

Production Capacity: 10-1300T/h

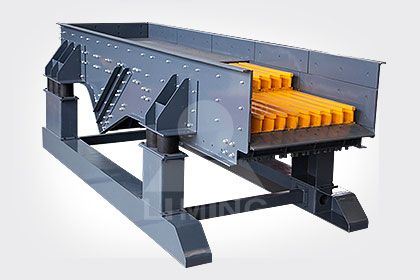

Circular Vibrating Screen is a multi-deck and high efficiency screen. The Vibrating Screen is worked through with Eccentric shaft, exciter and eccentric block in disciplinarian way in case to separate the Materials, which is widely used in grading in the industries of quarry, building material, chemical industry, etc.

Email: infosh@limingco-group.com

Fea tures

- 1.Cylinder eccentric shaft and eccentric block are adopted to make strong vibrating force.

- 2.Sieve beam and the box are connected by the high strength bolt.

- 3.The screen side plate is boiler Steel which has high strength and strong impact resistance.

- 4.The structure of small amplitude, high frequency, large obliquity makes the screen with high efficiency, large handling capacity, long life span, low compunction, and little noise.

Over view

Circular Vibrating Screen is a multi-deck and high efficiency screen. The Vibrating Screen is worked through with Eccentric shaft, exciter and eccentric block in disciplinarian way in case to separate the Materials, which is widely used in grading in the industries of quarry, building material, chemical industry, etc.

Working Principle

The vibrating screen uses the motor to drive the eccentric shaft to make the screen body periodically along with the direction of vibration force. The materials make circular movement on the screen to realize sieving. Circular vibrating screen consists of vibration source, screen body, screen mesh, shock absorbing device, base frame, etc. It has the features of reasonable structure and long durability.

Spec ifications

| Model | Screen size(mm) | layers | Screen mesh (mm) | Maximum feed size(mm) | Vibrating frequency (rpm) | Capacity(tph) | Power KW(HP) | Dimension (L×W×H) (mm) | Weight (t) |

| 2YZS1237 | 3700X1200 | 2 | 3-80 | 100 | 750-950 | 10-80 | 11(15) | 4570×1900×1200 | 3.1 |

| 3YZS1237 | 3700X1200 | 3 | 3-80 | 100 | 750-950 | 10-80 | 11(15) | 4730×1900×1650 | 3.8 |

| 2YZS1548 | 4800X1500 | 2 | 3-80 | 100 | 750-950 | 30-200 | 15(20) | 5740×2180×1200 | 4.1 |

| 3YZS1548 | 4800X1500 | 3 | 3-80 | 100 | 750-950 | 30-200 | 15(20) | 5910×2180×1650 | 4.8 |

| 2YZS1848 | 4800X1800 | 2 | 3-80 | 100 | 750-950 | 50-250 | 18.5(25) | 5740×2540×1200 | 4.5 |

| 3YZS1848 | 4800X1800 | 3 | 3-80 | 100 | 750-950 | 50-250 | 18.5(25) | 5910×2540×1650 | 5.5 |

| 2YZS1860 | 6000X1800 | 2 | 3-80 | 100 | 750-950 | 60-300 | 22(30) | 6960×2540×1200 | 5.1 |

| 3YZS1860 | 6000X1800 | 3 | 3-80 | 100 | 750-950 | 60-300 | 22(30) | 7130×2540×1650 | 6.2 |

| 4YZS1860 | 6000X1800 | 4 | 3-80 | 100 | 750-950 | 60-300 | 22(30) | 7300×2540×2100 | 7.3 |

| 2YZS2160 | 6000X2100 | 2 | 3-80 | 100 | 750-900 | 80-400 | 22(30) | 7010×2980×1380 | 6.8 |

| 3YZS2160 | 6000X2100 | 3 | 3-80 | 100 | 750-900 | 80-400 | 30(40) | 7160×2980×1780 | 8 |

| 4YZS2160 | 6000X2100 | 4 | 3-80 | 100 | 750-900 | 80-400 | 30(40) | 7370×2980×2240 | 9 |

| 2YZS2460 | 6000X2400 | 2 | 5-80 | 100 | 750-900 | 100-500 | 30(40) | 7010×3280×1380 | 7 |

| 3YZS2460 | 6000X2400 | 3 | 5-80 | 100 | 750-900 | 100-500 | 37(50) | 7160×3280×1780 | 8.5 |

| 4YZS2460 | 6000X2400 | 4 | 5-80 | 100 | 750-900 | 100-500 | 37(50) | 7370×3280×2240 | 10 |

| 2YK3X2675 | 7500X2600 | 2 | 5-150 | 350 | 700-900 | 80-1140 | 45(61) | 8450X3460X1720 | 12.4 |

| 3YK3X2675 | 7500X2600 | 3 | 5-150 | 350 | 700-900 | 80-1140 | 45(61) | 8650X3460X2270 | 15.8 |

| 2YKN3075 | 7500X3000 | 2 | 5-150 | 350 | 700-900 | 100-1300 | 2X37(50) | 8680X4060X1900 | 19.5 |

| 3YKN3075 | 7500X3000 | 3 | 5-150 | 350 | 700-900 | 100-1300 | 2X45(61) | 8910X4060X2525 | 23.5 |

Pro ject

Request a quote

-

Select model and place orders

Select the model and submit the purchase intention

-

Get the base price

Manufacturers take the initiative to contact and inform the lowest price

-

Plant inspection

Expert training guide, regular return visit

-

Sign the contract

Select the model and submit the purchase intention