Input size: Up to 330mm

Production Capacity: 100-790T/h

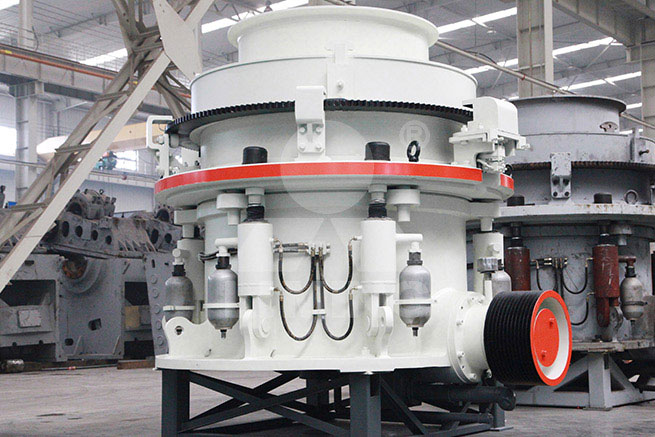

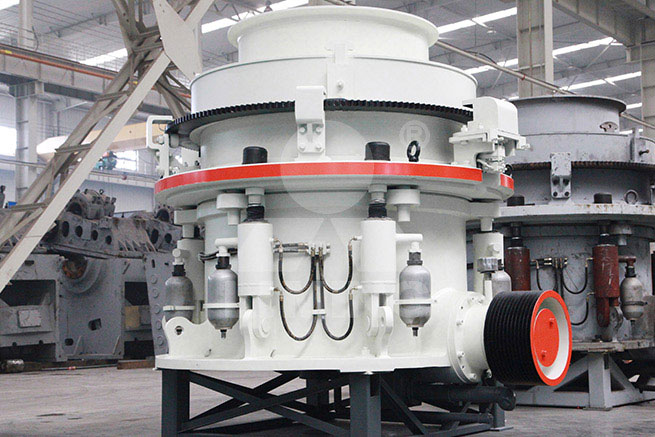

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. Unique interparticle crushing action, Advanced hydraulic system, Integration of the hydraulic station and lubrication system,Advanced liner retention technology,Much more reliable.The cone crusher ’s motor drives the horizontal axis of the cone crusher through triangle belt and pulley, the horizontal axis drive the eccentric shaft bush to rotate through gear transmission.

Email: infosh@limingco-group.com

Fea tures

-

Unique interparticle crushing action

1.HPT high performance hydraulic cone crusher feature a unique combination of crusher speed, throw, cavity design.

2.Inter-particle crushing works between materials that increases the working life of mantle and bowl liner.

3.Provide a more consistent gradation and superior products (cubicity). Better performance in the construction and sand making area. -

Advanced hydraulic system

1.Larger diameter tubing and larger capacity hydraulic accumulator improve the stability and response sensitivity.

2.Hydraulic motor setting adjustment and lock cylinder make it easy to reset the CSS. The hydraulic tramp release cylinders make it easy to pass tramp iron and clean the cavity. Less downtime will cut the maintenance costs. -

Integration of the hydraulic station and lubrication system

1.Integration of the hydraulic station and lubrication system features a small footprint installation space and easy maintenance.

2.1/5 of Lubrication oil consumption is saved compare with the similar model crushers from the competitors.

3.Germany AKG air cooling system avoids the disadvantage of water cooling system, such as lack of water and leakage of water.

4.Larger flow oil pump will guarantee the stability oil flow.

5.The addition of temperature sensors will keep track of the oil return temperature will connect the crusher hydraulic and lubrication system to the control system, which will guarantee the stable performance. -

Advanced liner retention technology

1.The thicker liners increase reliability and service life.

2.Advanced liner retention technology greatly simplifies the liner change, Epoxy resin is not needed, which will cut the manpower and time cost. -

Much more reliable

1.Equipped with the Siemens PLC and touch screen intelligent control system optimizes cone crusher operation convince and data saving.

2.Thanks to the advanced design, the bearings have a larger bearing area and larger bearing capacity and longer service life.

3.The overall casting frame with box beam design characterized by larger strength.

4.The interior of the crusher is protected from dust by the adoption of multiple sealing protection, such as positive pressure dust prevention system, U - T seal and contact-type spherical floating seal.

Over view

HPT series high efficiency Hydraulic Cone Crusher is a world-level cone crusher developed from the up-to-minute technology of Germany. The cone crusher not only improves the production capacity and crushing efficiency, but also widen the applying area, from limestone to basalt, from stone production to various are crushing. It has a second-to-non crushing performance in the work of medium-size crushing, fine crushing and super fine crushing. The crusher is the improved type of spring cone crusher and can be used to replace ordinary hydraulic cone crusher in the line of mining and construction. It is the most ideal equipment for large stone crushing factory and mining industry.

Working Principle

The crushing principle of Hydraulic Cone Crusher is finished between fixed cone plate and movable cone plate. The cone crusher ’s motor drives the horizontal axis of the cone crusher through triangle belt and pulley, the horizontal axis drive the eccentric shaft bush to rotate through gear transmission. The eccentric shaft drives the main shaft to make the movable cone plate swing at a regulated track from time to time, the materials are crushed due to constant pressed and crooked in the crushing cavity. The finished products are discharged from the discharging open.

Spec ifications

| Type | Cavity (coarse/fine) | Close Side feed opening(mm) | Min CSS (mm) | Capacity (tPh) | Power KW(HP) |

| HPT300 | C1 Extra Coarse | 230 | 25 | 220-440 | 250(350) |

| C2 Coarse | 210 | 20 | 190-380 | ||

| M Medium | 150 | 16 | 175-320 | ||

| F1 Fine | 105 | 13 | 110-260 | ||

| F2 Extra Fine | 80 | 10 | 100-240 | ||

| HPT500 | C1 Extra Coarse | 330 | 38 | 425-790 | 400(500) |

| C2 Coarse | 290 | 30 | 380-700 | ||

| M Medium | 210 | 22 | 330-605 | ||

| F1 Fine | 130 | 16 | 270-535 | ||

| F2 Extra Fine | 95 | 13 | 200-430 | ||

| HPT800 | C1 Extra Coarse | 350 | 38 | 545-1200 | 630(850) |

| C2 Coarse | 300 | 32 | 495-1050 | ||

| M Medium | 265 | 25 | 470-950 | ||

| F1 Fine | 220 | 17 | 385-730 | ||

| F2 Extra Fine | 150 | 14 | 310-600 | ||

| F3 Extra Fine | 90 | 10 | 260-550 |

Pro ject

Request a quote

-

Select model and place orders

Select the model and submit the purchase intention

-

Get the base price

Manufacturers take the initiative to contact and inform the lowest price

-

Plant inspection

Expert training guide, regular return visit

-

Sign the contract

Select the model and submit the purchase intention