Input size: 600-2800mm

Production Capacity: 2.26-147.8m³

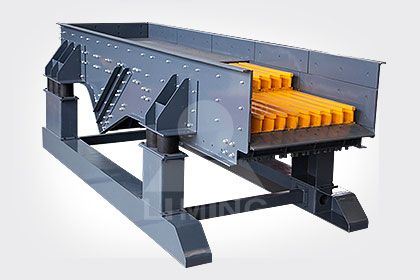

Rotary Dryer is used to dry materials like limestone, slag, clay, etc. It adopts X-type and H-type multi-segment material lifting plate.Material is fed at one end and discharged at the other end. In direct-type rotary dryers, hot gases move through the cylinder in direct contact with the material, either with or against the direction of its flow.

Email: infosh@limingco-group.com

Fea tures

- 1.It adopts X-type and H-type multi-segment material lifting plate.

- 2.New type fluidized bed combustion boiler is suitable for various kinds of coal.

- 3.Great improvement has been made on driven system of the dryer.

- 4.teeth-changeable gear is used, by this maintenance is easier.

- 5.The adoption of centralized control system enables automatic operation.

Over view

Rotary Dryer is used to dry materials like limestone, slag, clay, etc. It can be used in building materials, metallurgy, chemical industry and cement industry. The dryer is mainly made up of rotary barrel, material lifting plate, transmission device, support device, seat ring, etc. The dryer has advantage of scientific structure, good craftsmanship, high capacity, low consumption and easy maintenance.

Working Principle

Rotary dryer consist of a horizontally inclined rotating cylinder. Material is fed at one end and discharged at the other end. In direct-type rotary dryers, hot gases move through the cylinder in direct contact with the material, either with or against the direction of its flow. The cylinder is equipped with flights, which lift the material and shower it down through the hot gas stream.

Spec ifications

| Model | Diameter of Barrel(mm) | Length of Barrel(m) | Gradient(°) | Rotary speed(RPM) | Power(Kw) | Volume(m³) | |

| Φ0.6×8-12 | 600 | 8-12 | 3-5 | 8 | 4 | 2.26 | |

| Φ0.8×10-12 | 800 | 10-12 | 3-5 | 7.2 | 4 | 5.02 | |

| Φ1.0×10-12 | 1000 | 10-12 | 3-5 | 6.73 | 5.5 | 7.85 | |

| Φ1.2×12-18 | 1200 | 12-18 | 3-5 | 5.8 | 11-15 | 13.31 | |

| Φ1.5×12-18 | 1500 | 12-18 | 3-5 | 4.8 | 15-22 | 21.2 | |

| Φ1.8×12-18 | 1800 | 12-18 | 3-5 | 3.2 | 18.5-30 | 48.22 | |

| Φ2.2×12-22 | 2200 | 12-22 | 3-5 | 3 | 22-30 | 70.43 | |

| Φ2.8×15-24 | 2800 | 15-24 | 3-5 | 2.59 | 30-55 | 147.8 | |

Notice: Any change of European Type Jaw Crusher technical data shall not be advised additionally.

Pro ject

Request a quote

-

Select model and place orders

Select the model and submit the purchase intention

-

Get the base price

Manufacturers take the initiative to contact and inform the lowest price

-

Plant inspection

Expert training guide, regular return visit

-

Sign the contract

Select the model and submit the purchase intention