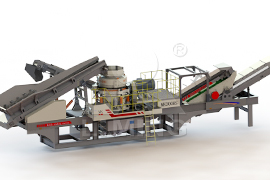

Input size: 0-930mm

Production Capacity: 100-650T/h

Primary Crushing Plant is equipped with high-efficiency jaw crusher and impact crusher, and millions of crushers have been installed worldwide since the end of the 20th century.There are crushing unit interchange system and feeding unit interchange system to meet different requirements. Application from one single mobile plant to multiply combined plants, 2.Equipped with high-efficiency jaw crusher as primary machine.

Email: infosh@limingco-group.com

Fea tures

- 1.Application from one single mobile plant to multiply combined plants

- 2.Equipped with high-efficiency jaw crusher as primary machine

- 3.Compact chassis frame, short length of transportation

- 4.Large capacity with pre-screening function

- 5.Optional switch for host to satisfy customer's need

- 6.Quick opening process with flexible parking function

- 7.Professional services for global customers

Over view

Primary Crushing Plant is equipped with high-efficiency jaw crusher and impact crusher, and millions of crushers have been installed worldwide since the end of the 20th century.

There are 8 types of jaw crushers and 4 types of impact crushers you can choose for mobile crushing, whose final products are good shape. The greatest advantages of European Type Crusher are that the final products are cube-shaped and well-distributed. Besides, there are no cracks in products.

Working Principle

There are crushing unit interchange system and feeding unit interchange system to meet different requirements. That is to say, in a short time, vibrating feeders with different models are interchangeable in the same mobile crusher, and jaw crusher and impact crusher can interchange, either. Basing on cooperation between high-efficiency equipment, the perfect plant has advantages of wide usage and comprehensive functions, which can maximize the value of customers.

Spec ifications

| Model | Feeding Equipment | Crushing Equipment | Max. preparedness capacity(t/h) | Overall Dimension | Weight (t) | ||

| Model | Model | Max. Feeding Size(mm) |

output (t/h) |

Transport dimension (need tear-down) | |||

| KE600-1 | TSW0936 | PE600×900Ⅱ | 500 | 90-180 | 100-210 | 12150×2600×3950(mm) | 43 |

| KE750-1 | TSW1139 | PE750×1060 | 630 | 110-300 | 130-330 | 13000×2850×4400mm | 61 |

| KE760-1 | TSW1139 | PEW760 | 640 | 150-310 | 170-330 | 13000×2800×4200(mm) | 55 |

| KE860-1 | TSW1345 | PEW860 | 720 | 200-420 | 230-450 | 14600×3000×4500(mm) | 64 |

| KE1100-1 | TSW1548 | PEW1100 | 930 | 300-600 | 350-650 | 14050×2900×4000(mm) | 96 |

| KJ98-1 | TSW1139 | HJ98 | 560 | 110-350 | 130-370 | 12150×2600×3950mm | 44 |

| KJ110-1 | TSW1345 | HJ110 | 660 | 215-490 | 235-520 | 13200×3000×4400(mm) | 58 |

| KJ125-1 | TSW1345 | HJ125 | 800 | 280-620 | 310-650 | 14600×3000×4500(mm) | 68 |

| KF1214Ⅱ-1 | TSW0936 | PFW1214Ⅱ | 500 | 110-190 | 120-210 | 12150×2600×3980(mm) | 48 |

| KF1214Ⅱ-1 | TSW1139 | PFW1214Ⅱ | 500 | 110-190 | 140-230 | 13000×2800×4200(mm) | 53 |

| KF1315Ⅱ-1 | TSW1345 | PFW1315Ⅱ | 600 | 180-280 | 190-310 | 14600×3100×4500(mm) | 61 |

| KF1415Ⅱ-1 | TSW1548 | PFW1415Ⅱ | 700 | 280-450 | 310-480 | 14050×3000×4000(mm) | 74 |

Pro ject

Request a quote

-

Select model and place orders

Select the model and submit the purchase intention

-

Get the base price

Manufacturers take the initiative to contact and inform the lowest price

-

Plant inspection

Expert training guide, regular return visit

-

Sign the contract

Select the model and submit the purchase intention